Introduction

In modern construction, especially in projects with curved structures such as round columns, underpasses, overpasses, and curved walls, the demand for curved film faced plywood is rapidly increasing. This specialized plywood formwork material helps achieve faster, more precise, and more cost-efficient construction compared to traditional solutions.

What is Curved Film Faced Plywood?

Curved film coated plywood is a type of film faced plywood specially designed to be bent or curved to a specific radius, making it ideal for concrete formwork on curved surfaces.

Main structure of curved plywood formwork:

- Core veneer: usually made from eucalyptus, acacia, or plantation timber for strength.

- Adhesive: water-resistant glue (Phenolic Glue, WBP Glue) prevents delamination.

- Film overlay: imported film paper with waterproof, scratch-resistant, and high-strength properties.

👉 The biggest difference lies in its ability to bend without cracking, allowing flexible shaping for a wide range of construction projects.

Key Features of Curved Plywood

- Flexible forming: can be bent to various radii (commonly 1–4 meters).

- High durability: multiple layers of core veneer pressed tightly to avoid warping.

- Water & moisture resistance: thanks to its waterproof film coating.

- Reusable: can be used multiple times, lowering overall formwork costs.

- Smooth surface finish: produces concrete surfaces with minimal plastering required.

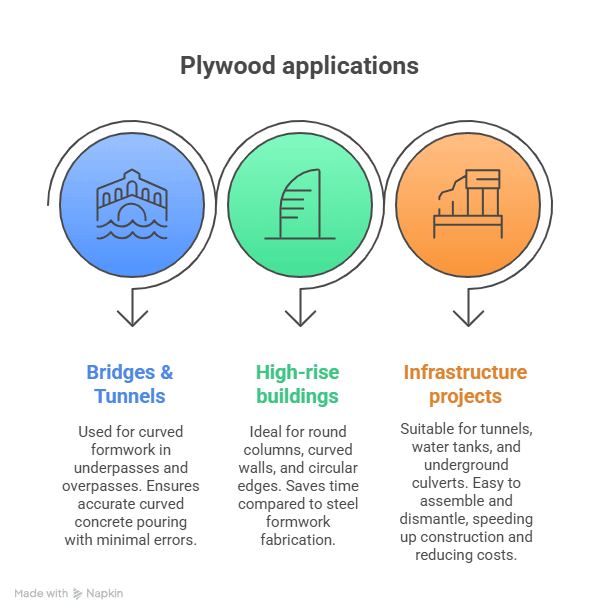

Applications of Curved Film-Faced Plywood in Construction

🏗️ Bridges & Tunnels

- Used for curved formwork in underpasses and overpasses.

- Ensures accurate curved concrete pouring with minimal errors.

🏢 High-rise buildings & architectural projects

- Ideal for round columns, curved walls, and circular edges.

- Saves time compared to steel formwork fabrication.

🌉 Infrastructure projects

- Suitable for tunnels, water tanks, and underground culverts.

- Easy to assemble and dismantle, speeding up construction and reducing costs.

Comparison: Curved Film Coated Plywood vs. Other Formwork Materials

| Criteria | Curved Film Faced Plywood | Steel Formwork | Flat Film Faced Plywood |

|---|---|---|---|

| Forming ability | Flexible bending for curves | Complex fabrication required | Only for flat surfaces |

| Weight | Lightweight, easy to handle | Heavy, difficult to move | Lightweight |

| Cost | Medium, reusable multiple times | High | Low |

| Typical application | Curved structures, round columns | Large-scale, heavy load works | Residential & flat structures |

👉 Clearly, curved plywood formwork offers the best balance between cost and flexibility, making it a preferred choice for modern construction.

Expert Recommendations from HG Plywood

With years of experience supplying film faced plywood for major projects, HG Plywood recommends:

- Choose products certified to international standards (E1, CARB, TSCA).

- Ensure film coating thickness ≥ 120 g/m² for longer durability.

- Select WBP waterproof adhesive for maximum reuse cycles.

Conclusion

Curved film coated plywood is the optimal solution for curved concrete formwork in infrastructure and modern architectural projects. With advantages such as flexible bending, high durability, and cost savings, this material is becoming increasingly popular in Vietnam and international markets.

👉 Looking for high-quality curved film faced plywood?

Contact HG Plywood today for technical consultation and competitive pricing!

📞 Contact HG Plywood

H&G Import and Export Co., Ltd

🌏 Website: hgwoods.com

📞 Hotline: (+84) 9656 09 153 (WhatsApp)

📧 Email: hgplywood@gmail.com

🏭 Address: Dinh Xuyen, Gia Lam, Hanoi, Vietnam

Leave a Reply