In modern construction, film faced plywood is one of the most widely used materials for concrete formwork thanks to its moisture resistance, durability, and easy removal after pouring. There are two common types: flat film faced plywood and curved (bendy) film faced plywood.

Each type has unique strengths and limitations. Understanding their differences helps contractors and architects choose the right material, optimize costs, and improve construction efficiency.

1. Definition & Production

1.1 Flat Film Faced Plywood

Flat film faced plywood is a standard panel with both surfaces coated by a waterproof film layer.

- Applications: concrete slabs, walls, beams, and straight formwork.

- Standard size: 1220 × 2440 mm.

- Thickness range: 6.5 mm – 30 mm (commonly 12, 15, 18 mm).

- Core material: eucalyptus, poplar, acacia, or mixed plantation wood.

- Glue: water-resistant phenolic or WBP glue to prevent delamination when exposed to wet concrete.

1.2 Curved / Bendy Film Faced Plywood

Curved (or bendy) film faced plywood is specially manufactured to bend along a certain radius without cracking or breaking.

- Applications: circular columns, curved walls, tunnels, bridges, and round-shaped structures.

- Common thickness: thinner panels (4 mm, 6 mm, 8 mm) for flexibility.

- Film coating: durable phenolic film (120 g/m² or higher) for moisture resistance and smooth concrete finish.

- Core & glue: designed to maintain strength even when bent, using high-quality hardwood veneer and WBP glue.

2. Technical Comparison

| Criteria | Flat Film Faced Plywood | Curved Film Faced Plywood |

|---|---|---|

| Formability | Only for flat surfaces (slabs, walls, beams). | Can bend to a defined radius, suitable for curved columns, arches, tunnels. |

| Thickness | 12 mm, 15 mm, 18 mm are standard. | 4 mm – 8 mm for flexibility. |

| Reuse Cycles | Up to 10–15 times depending on quality and maintenance. | Similar or slightly lower reuse cycles due to bending stress. |

| Strength | Higher load capacity thanks to thicker panels. | Lower strength (due to thin design for bending). |

| Weight | Heavier but stable. | Lighter for easier handling. |

| Cost | More affordable, mass-produced. | Higher cost due to special production process. |

3. Pros & Cons

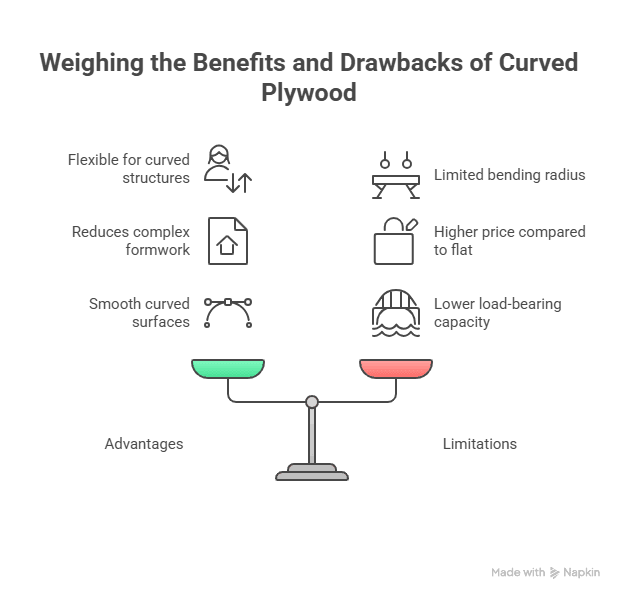

Advantages of Curved Film Faced Plywood

- Flexible for round or curved structures.

- Reduces the need for complex steel formwork.

- Provides smooth curved concrete surfaces with fewer joints.

Limitations:

- Limited bending radius (too small may cause cracks).

- Higher price compared to flat plywood.

- Lower load-bearing capacity.

Advantages of Flat Film Faced Plywood

- Stronger and more durable at the same thickness.

- Lower cost, widely available in the market.

- Easy to cut, handle, and apply for most projects.

Limitations:

- Cannot be used directly for curved formwork.

- Requires modification or steel reinforcement for curved designs.

4. Practical Applications

Flat Film Faced Plywood

- Concrete slabs, straight walls, beams, and columns.

- Widely used in residential buildings, high-rise structures, and commercial projects.

Curved Film Faced Plywood

- Bridges, tunnels, round columns, and arched ceilings.

- Ideal for modern architecture requiring smooth curves.

5. Expert Recommendations

When selecting between curved and flat film faced plywood:

- Define the minimum bending radius required for your project.

- Consider reuse cycles: high-quality flat plywood can be reused 10–15 times.

- Choose phenolic film ≥120 g/m² for better durability.

- Always use WBP or phenolic glue to ensure waterproof bonding.

- Combine both flat and curved plywood in large-scale projects to optimize cost.

6. Conclusion

Both curved film faced plywood and flat film faced plywood play essential roles in construction. Flat panels are cost-effective for standard formwork, while curved panels provide flexibility for unique designs like round columns, bridges, and tunnels.

Choosing the right type not only saves costs but also ensures construction quality and efficiency.

📌 FAQ

Q1: What is curved film faced plywood used for?

A1: Curved film faced plywood is used in construction projects that require curved formwork such as round columns, tunnels, bridges, and arched ceilings. It allows accurate bending without cracks and provides a smooth concrete surface.

Q2: How many times can film faced plywood be reused?

A2: High-quality flat film faced plywood can be reused 10–15 times, while curved plywood can be reused a similar number of times if maintained properly.

Q3: What is the difference between flat film faced plywood and curved film faced plywood?

A3: Flat film faced plywood is designed for straight formwork like slabs and walls, offering higher load capacity at a lower cost. Curved film faced plywood is more flexible, suitable for circular or arched structures, but generally more expensive.

Q4: Which type of film faced plywood is more cost-effective?

A4: Flat film faced plywood is more cost-effective for standard projects. However, curved film faced plywood saves time and labor in projects requiring complex round or arched designs.

Q5: Where can I buy film faced plywood in Vietnam?

A5: You can buy high-quality flat and curved film faced plywood from HG Plywood. Contact us at 📞(+84) 9656 09 153 (WhatsApp) for expert advice and a competitive quotation.

👉 Looking for high-quality film faced plywood in Vietnam?

Contact HG Plywood today for expert consultation and the best quotation.

📞 Contact Information

H&G Import and Export Co., Ltd

🌏 Website: hgwoods.com

📞 Hotline: (+84) 9656 09 153 (WhatsApp)

📧 Email: hgplywood@gmail.com

🏭 Address: Dinh Xuyen, Gia Lam, Hanoi, Vietnam

Leave a Reply